Freeze Drying Candy: A Comprehensive Guide to Preservation and Delectable Treats

Freeze-drying, a method of food preservation that removes moisture while maintaining flavor and nutrients, has captured the culinary world's attention. When it comes to freeze-drying candy, understanding the time involved is essential. Freeze-drying candy offers extended shelf life, enhances flavors, and creates unique textures.

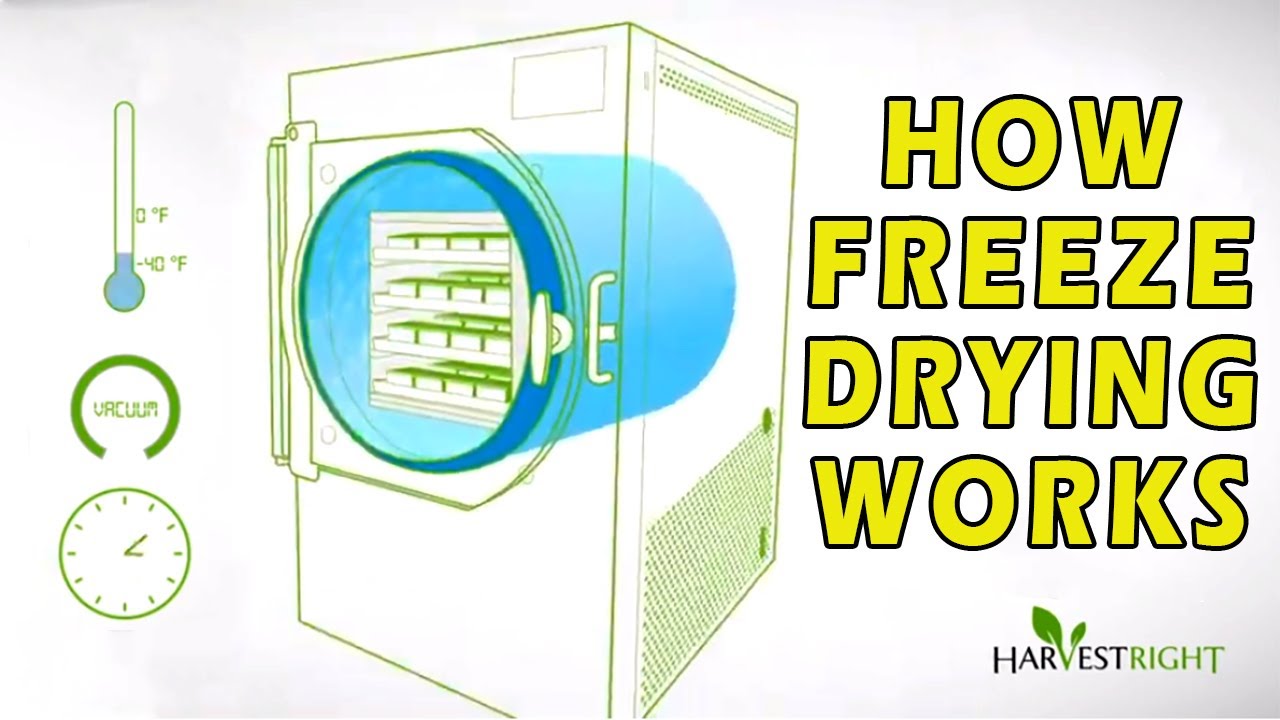

The freeze-drying process begins with freezing the candy at ultra-low temperatures. Subsequently, the frozen candy is placed in a vacuum chamber where the pressure is reduced, causing the water within the candy to sublime directly from a solid to a vapor. This process effectively removes up to 98% of the moisture content, preserving the candy's integrity and extending its shelf life significantly.

Read also:## How Long Does it Take to Freeze Dry Candy?Did Luke Combs Brother Actually Die Unraveling The Truth Behind The Rumors

Understanding the time involved in freeze-drying candy is crucial for achieving optimal results and preserving the candy's quality. Here are five key aspects to consider:

- Candy Type: Different types of candy, such as hard candy, gummies, and chocolates, have varying moisture contents and densities, affecting freeze-drying time.

- Candy Size: Smaller candies freeze-dry faster than larger ones due to increased surface area and reduced moisture content.

- Freeze-Dryer Capacity: The size and capacity of the freeze-dryer can impact the processing time, as larger batches may require longer cycles.

- Temperature: The temperature of the freeze-dryer's chamber plays a crucial role, with lower temperatures resulting in longer drying times.

- Desired Moisture Level: The desired final moisture content of the candy influences the duration of the freeze-drying process.

These aspects are interconnected and should be carefully considered to determine the optimal freeze-drying time for specific candy types and desired outcomes. By understanding these factors, individuals can effectively plan and execute the freeze-drying process to achieve high-quality, long-lasting candy treats.

Candy Type

The type of candy significantly influences the freeze-drying time due to varying moisture contents and densities. Hard candies, for example, have a lower moisture content and higher density compared to gummies. As a result, hard candies require a longer freeze-drying time to remove the same amount of moisture.

Gummies, on the other hand, have a higher moisture content and lower density, leading to a shorter freeze-drying time. Chocolates, with their unique composition of cocoa solids, fats, and sugars, exhibit a moisture content and density that fall between hard candies and gummies. Consequently, chocolates require an intermediate freeze-drying time.

Understanding the relationship between candy type and freeze-drying time is crucial for optimizing the process. By considering the specific characteristics of each candy type, manufacturers can determine appropriate freeze-drying cycles to achieve the desired moisture level and preserve the candy's quality.

In practice, this understanding enables confectioners to efficiently plan production schedules, ensuring that different types of candy undergo tailored freeze-drying processes. It also allows for precise control over the final moisture content, affecting shelf life, texture, and flavor.

Read also:Connor Mcgregor Height In Feet A Comprehensive Overview

Candy Size

The relationship between candy size and freeze-drying time is directly proportional. Smaller candies freeze-dry faster than larger ones because of two primary factors: increased surface area and reduced moisture content.

Firstly, smaller candies have a larger surface area relative to their volume compared to larger candies. This increased surface area allows for more efficient moisture removal during the freeze-drying process. With a greater surface area exposed to the vacuum environment, water molecules can more readily escape from the candy, leading to faster drying times.

Secondly, smaller candies typically have a lower moisture content than larger candies. This is because smaller candies have a smaller volume, resulting in less water content overall. Consequently, there is less moisture to remove during the freeze-drying process, further contributing to reduced drying times.

Understanding the relationship between candy size and freeze-drying time is crucial for optimizing the freeze-drying process. By considering the size of the candies, manufacturers can adjust freeze-drying cycles to achieve the desired moisture level efficiently. This understanding also enables manufacturers to plan production schedules effectively, ensuring that different sizes of candy undergo tailored freeze-drying processes.

In practice, this understanding has several practical applications. For example, manufacturers can prioritize freeze-drying smaller candies first to maximize production efficiency. This allows them to allocate freeze-drying resources optimally, ensuring that smaller candies are not held back by the longer drying times of larger candies.

Freeze-Dryer Capacity

The capacity of the freeze-dryer plays a crucial role in determining the processing time for freeze-drying candy. Larger freeze-dryers can accommodate larger batches of candy, which leads to increased drying times. This is because larger batches require more time for the water vapor to be removed from the candy. Additionally, larger freeze-dryers may have more shelves or trays, which increases the distance that the water vapor must travel to reach the condenser. This can also contribute to longer drying times.

The size of the freeze-dryer is also an important factor to consider. Smaller freeze-dryers may not be able to accommodate large batches of candy, which can lead to longer processing times. Additionally, smaller freeze-dryers may have less powerful refrigeration systems, which can also lead to longer drying times.

Understanding the relationship between freeze-dryer capacity and processing time is critical for optimizing the freeze-drying process. By choosing the right size and capacity freeze-dryer, manufacturers can ensure that their candy is freeze-dried efficiently and effectively.In practice, this understanding has several practical applications. For example, manufacturers can use smaller freeze-dryers for smaller batches of candy, which can save time and energy. Additionally, manufacturers can use larger freeze-dryers for larger batches of candy, which can increase production efficiency.

In summary, the capacity of the freeze-dryer is an important factor to consider when freeze-drying candy. By choosing the right size and capacity freeze-dryer, manufacturers can optimize the freeze-drying process and produce high-quality freeze-dried candy.Temperature

In the context of freeze-drying candy, temperature plays a pivotal role in determining the duration of the process. Lower temperatures lead to extended drying times, while higher temperatures can accelerate the process. Understanding the influence of temperature is essential for optimizing freeze-drying parameters and achieving the desired results.

- Condenser Temperature: The condenser temperature directly impacts the rate of moisture removal. Lower condenser temperatures enhance the condensation process, effectively removing water vapor from the freeze-dryer's chamber. However, lower condenser temperatures also slow down the overall drying process, leading to longer drying times.

- Product Temperature: The temperature of the candy itself influences the freeze-drying process. Lower product temperatures promote slower sublimation, the process where water transforms directly from a solid to a gas. This results in longer drying times as the candy takes more time to reach the desired moisture level.

- Heat Transfer: Temperature gradients within the freeze-dryer affect heat transfer rates. Proper heat transfer is crucial for efficient moisture removal. Lower temperatures can hinder heat transfer, prolonging the drying process.

- Energy Consumption: Lower temperatures demand more energy to maintain the required freezing conditions. Extended drying times due to lower temperatures can increase energy consumption, impacting production costs and sustainability.

In summary, temperature plays a critical role in determining the freeze-drying time for candy. Comprehensive understanding of the relationship between temperature and drying time enables manufacturers to fine-tune their freeze-drying processes, optimize production efficiency, and achieve high-quality freeze-dried candy products.

Desired Moisture Level

The desired moisture level is a critical factor in determining the duration of the freeze-drying process for candy. This is because the amount of moisture that needs to be removed from the candy directly affects the length of time it will take to dry. Candy with a higher desired moisture level will take longer to freeze-dry than candy with a lower desired moisture level.

For example, if you are making hard candy, you will want to remove as much moisture as possible to create a hard and brittle candy. This will require a longer freeze-drying time than if you are making a soft and chewy candy, which will have a higher desired moisture level.

Understanding the relationship between desired moisture level and freeze-drying time is important for optimizing the freeze-drying process. By carefully controlling the moisture level, manufacturers can ensure that their candy has the desired texture and quality.

In practice, this understanding has several practical applications. For example, manufacturers can use freeze-drying to create candy with a variety of textures, from hard and brittle to soft and chewy. They can also use freeze-drying to create candy with different flavors and colors. By controlling the freeze-drying process, manufacturers can create candy that meets the specific needs of their customers.

In summary, the desired moisture level is a critical component of the freeze-drying process for candy. By understanding the relationship between desired moisture level and freeze-drying time, manufacturers can optimize the process to create candy with the desired texture, quality, and flavor.FAQs on Freeze-Drying Candy

This section addresses frequently asked questions to provide further clarification and insights into the freeze-drying process for candy.

Question 1: How long does it typically take to freeze dry candy?

Answer: The freeze-drying time for candy can vary depending on several factors, including candy type, size, and the capacity and temperature of the freeze-dryer. Generally, it can take anywhere from 8 to 48 hours to completely freeze-dry candy.

Question 2: Is it possible to freeze dry any type of candy?

Answer: Yes, most types of candy can be freeze-dried, including hard candies, gummies, chocolates, and taffy. However, candies with high moisture content or delicate textures may require special considerations during the freeze-drying process.

Question 3: How does the size of the candy affect the freeze-drying time?

Answer: Smaller candies have a larger surface area relative to their volume, allowing for faster moisture removal and shorter freeze-drying times compared to larger candies.

Question 4: What is the optimal temperature for freeze-drying candy?

Answer: The optimal temperature for freeze-drying candy depends on the type of candy and the desired moisture level. Generally, lower temperatures result in longer drying times, while higher temperatures can accelerate the process.

Question 5: How do I know when my candy is fully freeze-dried?

Answer: Freeze-dried candy will be hard and brittle, with no signs of moisture or stickiness. You can also use a moisture analyzer to accurately determine the moisture content and ensure complete freeze-drying.

Question 6: What are the benefits of freeze-drying candy?

Answer: Freeze-drying candy offers several benefits, including extended shelf life, enhanced flavors, unique textures, and preservation of nutrients.

These FAQs provide a comprehensive overview of key aspects related to freeze-drying candy. Understanding these factors enables effective planning and execution of the freeze-drying process to achieve high-quality, long-lasting candy treats.

In the next section, we will explore advanced techniques and considerations for freeze-drying candy, delving deeper into the science behind this innovative preservation method.

### Tips for Freeze-Drying CandyThis section provides practical tips and guidelines to optimize the freeze-drying process for candy, ensuring high-quality results and successful outcomes.

Tip 1: Choose the Right Candy: Not all candies are suitable for freeze-drying. Candies with high moisture content or delicate textures may require special considerations or may not be suitable for freeze-drying.

Tip 2: Prepare the Candy Properly: Before freeze-drying, ensure the candy is clean, free of any impurities, and cut into appropriate sizes for efficient drying.

Tip 3: Use a Reliable Freeze-Dryer: Invest in a freeze-dryer that meets your specific needs in terms of capacity, temperature control, and functionality.

Tip 4: Set the Correct Temperature: The optimal temperature for freeze-drying candy depends on the type of candy and desired moisture level. Lower temperatures result in longer drying times but better preservation of delicate flavors and textures.

Tip 5: Monitor the Freeze-Drying Process: Regularly check the progress of the freeze-drying process to ensure proper moisture removal and prevent over-drying.

Tip 6: Store Freeze-Dried Candy Properly: Store freeze-dried candy in airtight containers or packaging to prevent moisture absorption and maintain its quality and shelf life.

Tip 7: Experiment with Different Candies and Techniques: Freeze-drying offers endless possibilities for experimentation. Try freeze-drying different types of candy and explore various techniques to create unique and innovative treats.

Key Takeaways: By following these tips, you can effectively freeze-dry candy, preserving its flavors, textures, and nutritional value while extending its shelf life. Freeze-drying opens up exciting opportunities for culinary creativity and the production of high-quality candy products.

In the concluding section, we will delve into the future of freeze-drying technology and explore emerging trends and innovations that are shaping the candy industry and beyond.

Conclusion

Freeze-drying candy is a unique and innovative method for preserving and enhancing candies. Understanding the factors that influence freeze-drying time is essential to achieve optimal results. Key considerations include candy type, size, freeze-dryer capacity, temperature, and desired moisture level. By carefully controlling these parameters, manufacturers can tailor the freeze-drying process to specific candy products.

Freeze-drying offers several benefits, including extended shelf life, enhanced flavors, unique textures, and preservation of nutrients. It opens up new possibilities for culinary creativity and the production of high-quality candy treats. However, the freeze-drying time can vary depending on the specific candy and desired outcomes, and it is important to carefully monitor the process to ensure proper moisture removal and prevent over-drying.

As freeze-drying technology continues to advance, we can expect even more innovative applications and exciting developments in the candy industry and beyond. This technology holds great potential for creating new and delicious candy products that meet the demands of consumers seeking high-quality, long-lasting treats.